Amphenol PCD

Product Design

Engineering

Co-op

Beverly MA, July 2022 - January 2023

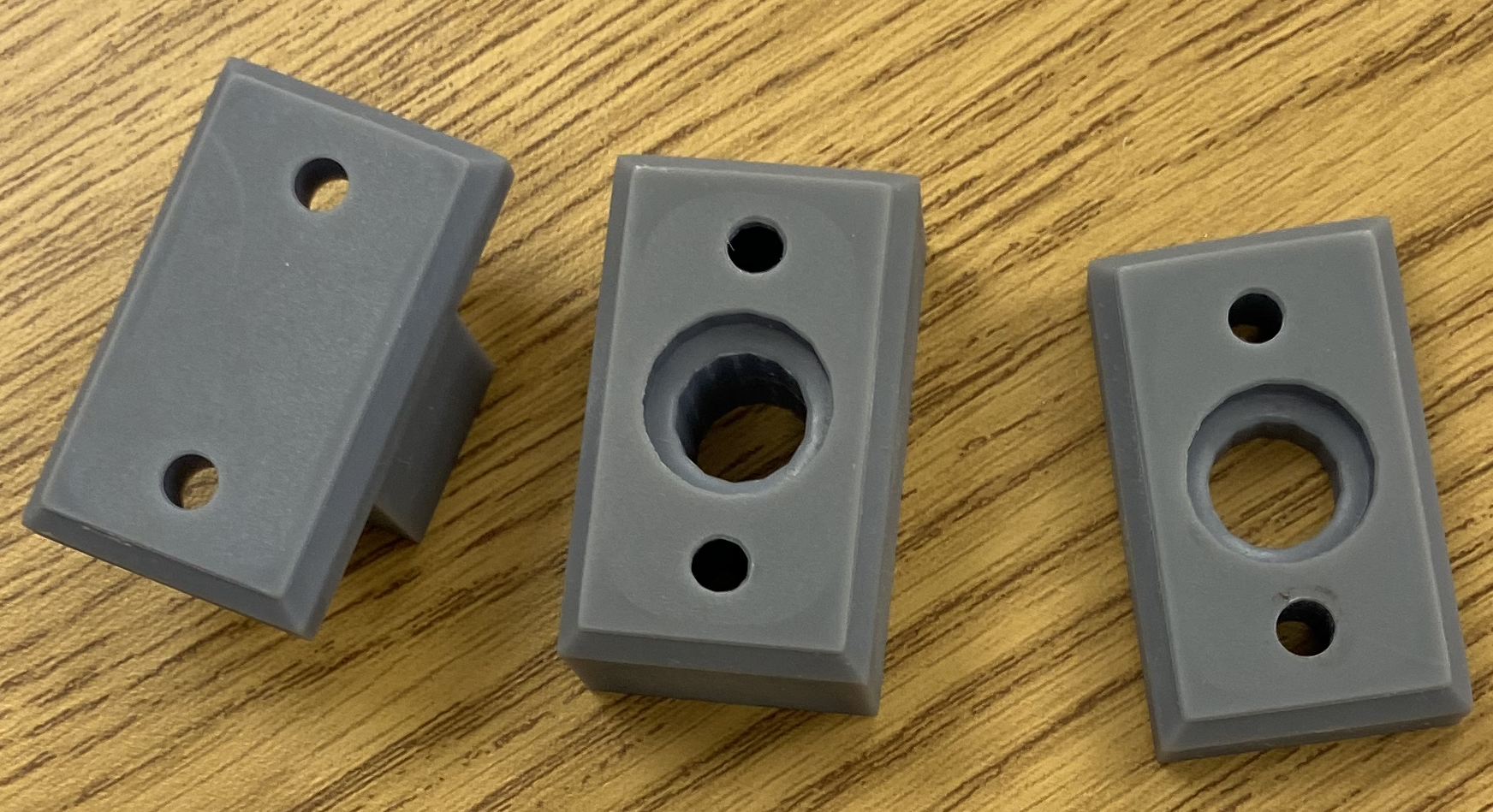

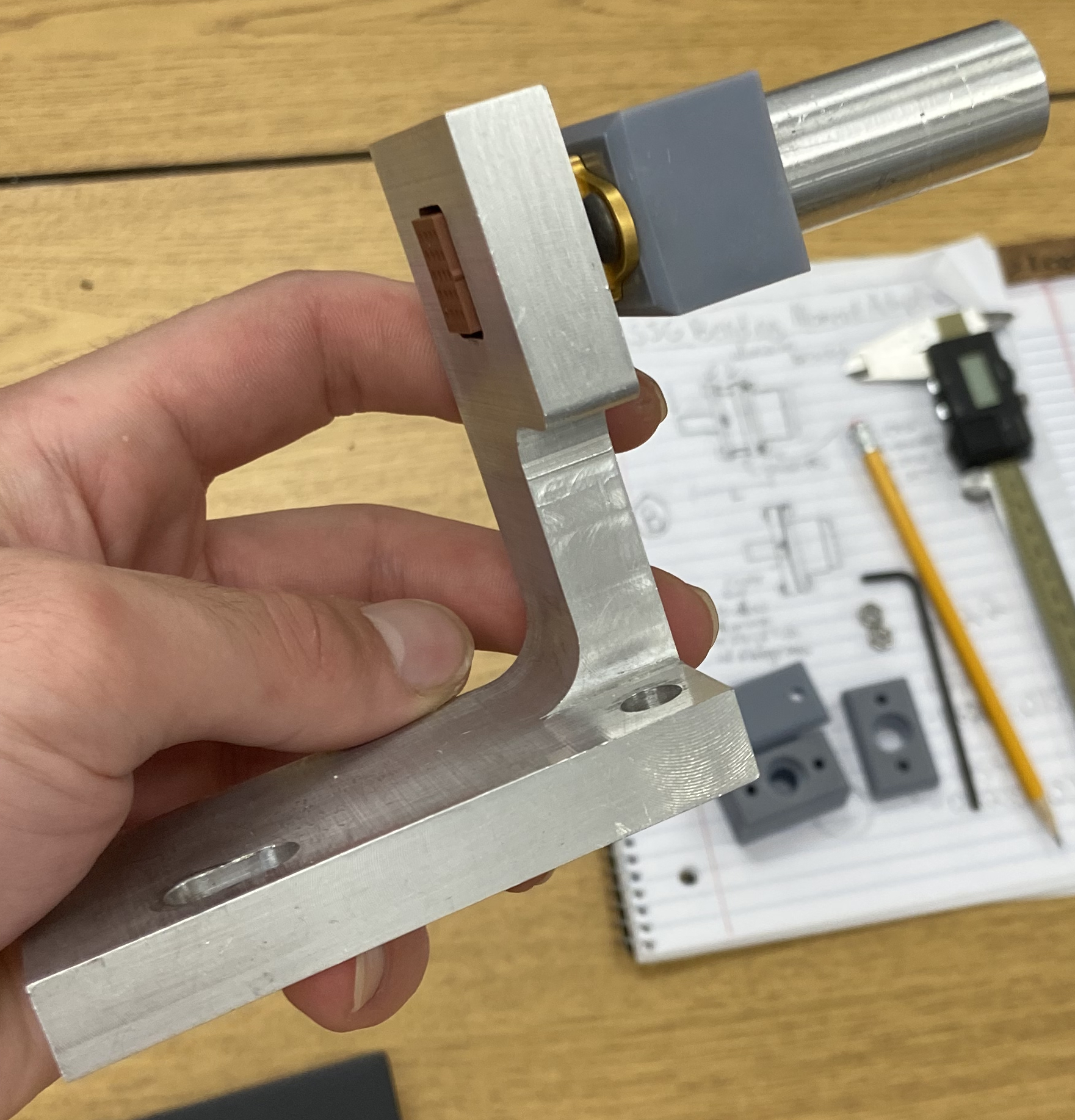

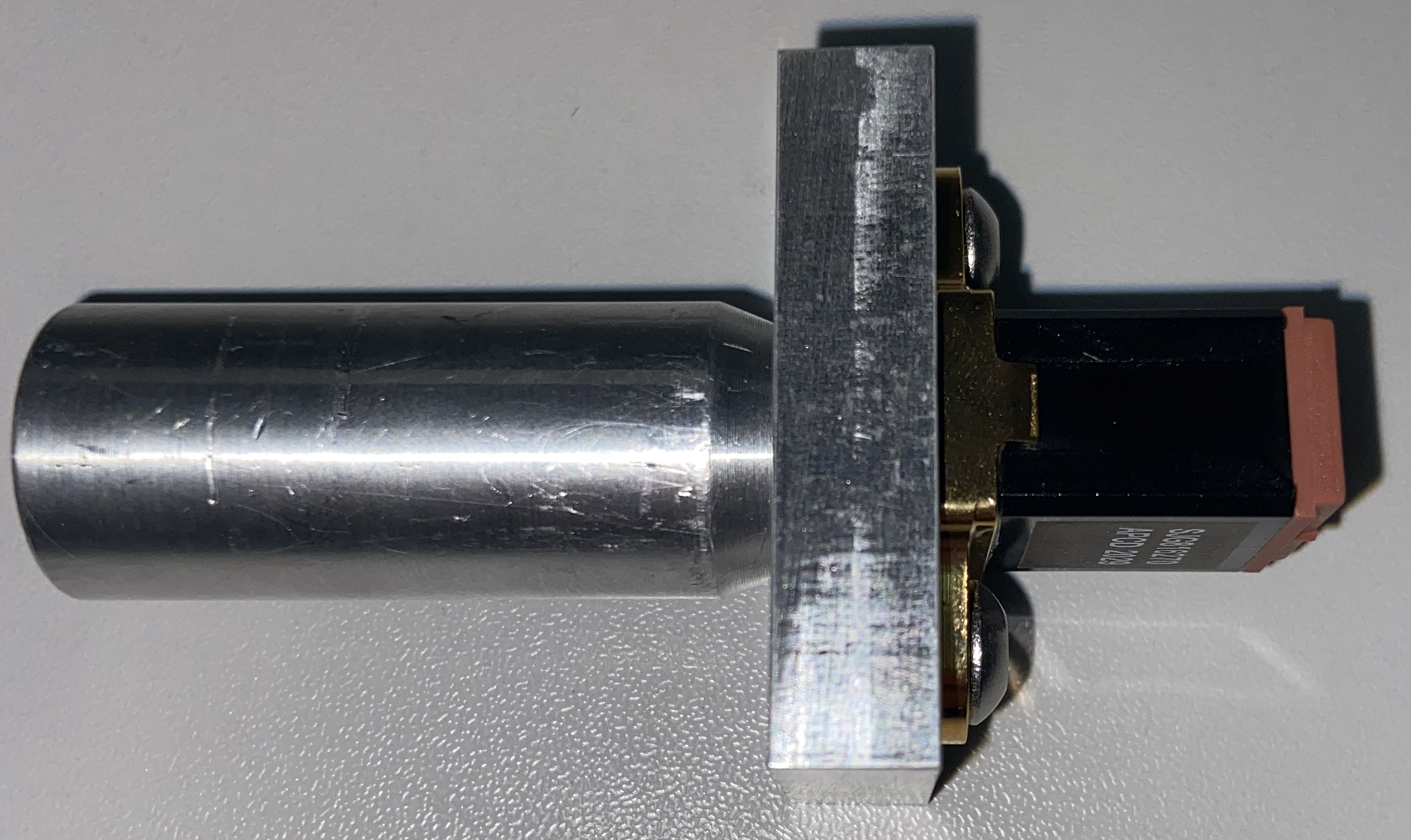

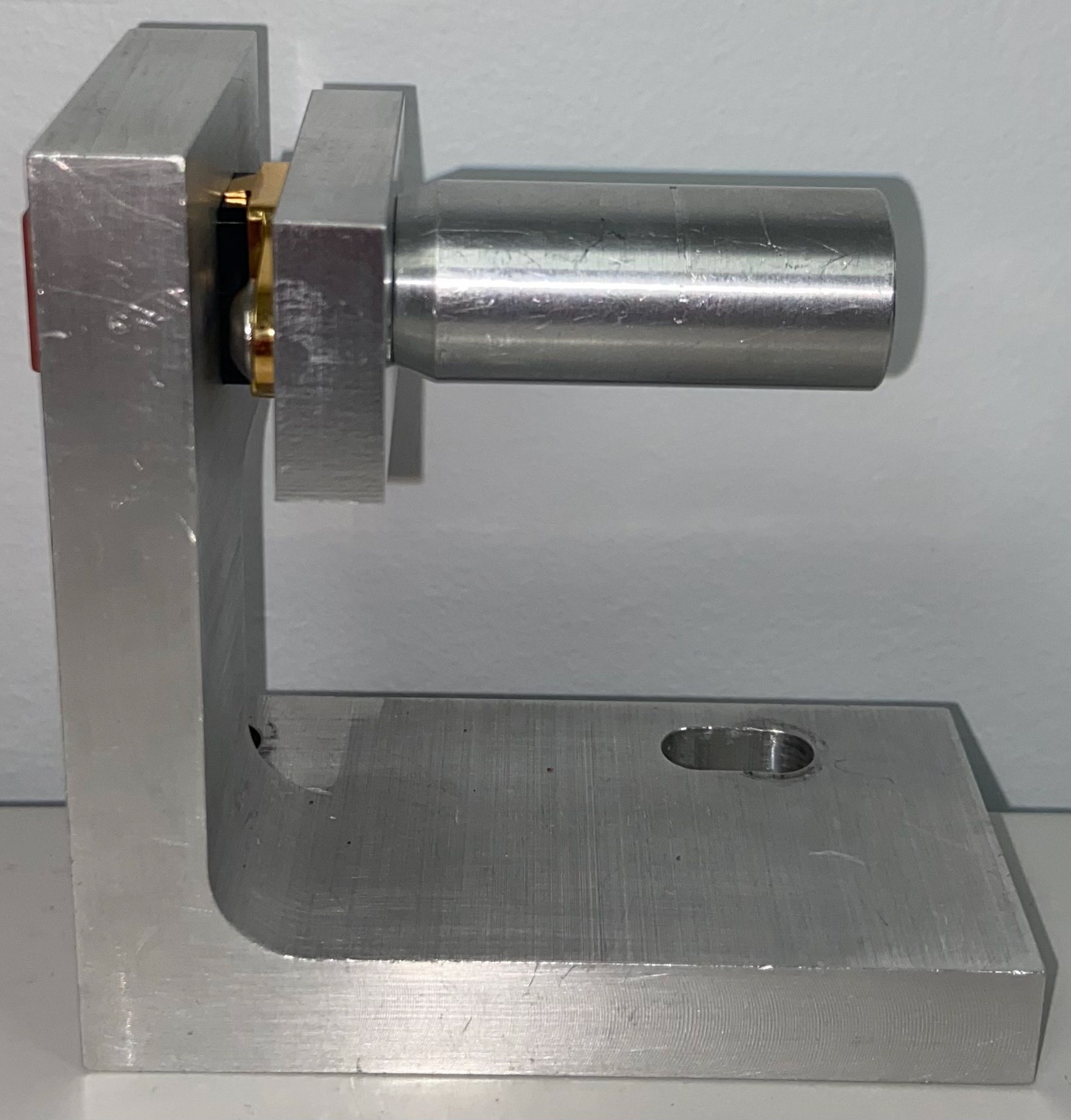

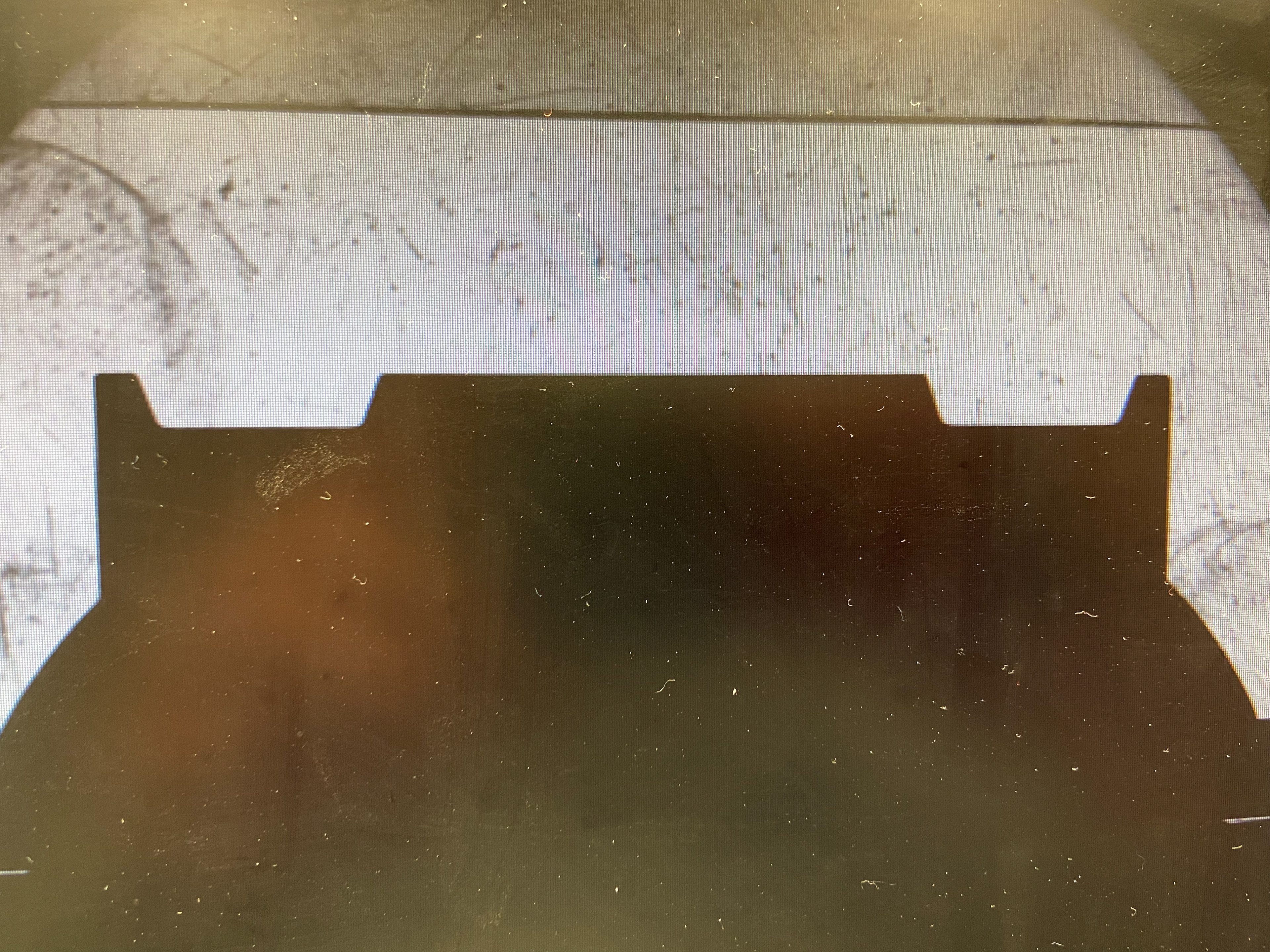

Torque Test Fixture

Design a new fixture to test SJG connector's strength against an applied bending moment

Action.

Modeled in CAD using Creo PTC, and 3D printed early prototypes for test-fit with connector. Worked hands-on in machine shop to mill final fixture out of stock aluminum. Tapped screw holes to eliminate need for nut tightening/removal during quality testing. Added a counterbore for through-bolt that threads into a pre-existing testing rod.

Outcomes

Developed my CAD modeling skills as I worked with the product model to develop a mating fixture. Grew my 3D printing skills as I became more proficient with the optimal techniques for resin printing. Learned about tolerances and was introduced to GD&T as I prepared drawings to send out for machining.

SJG Connector

Juggernaut Case Modeling

Created a digital CAD model of a heavy-duty phone case from real physical version. Model was used by another company engineer to design a tight-fit mating connector. Used Keyence machine to photographically obtain high-accuracy measurements of case features to replicate in Creo.

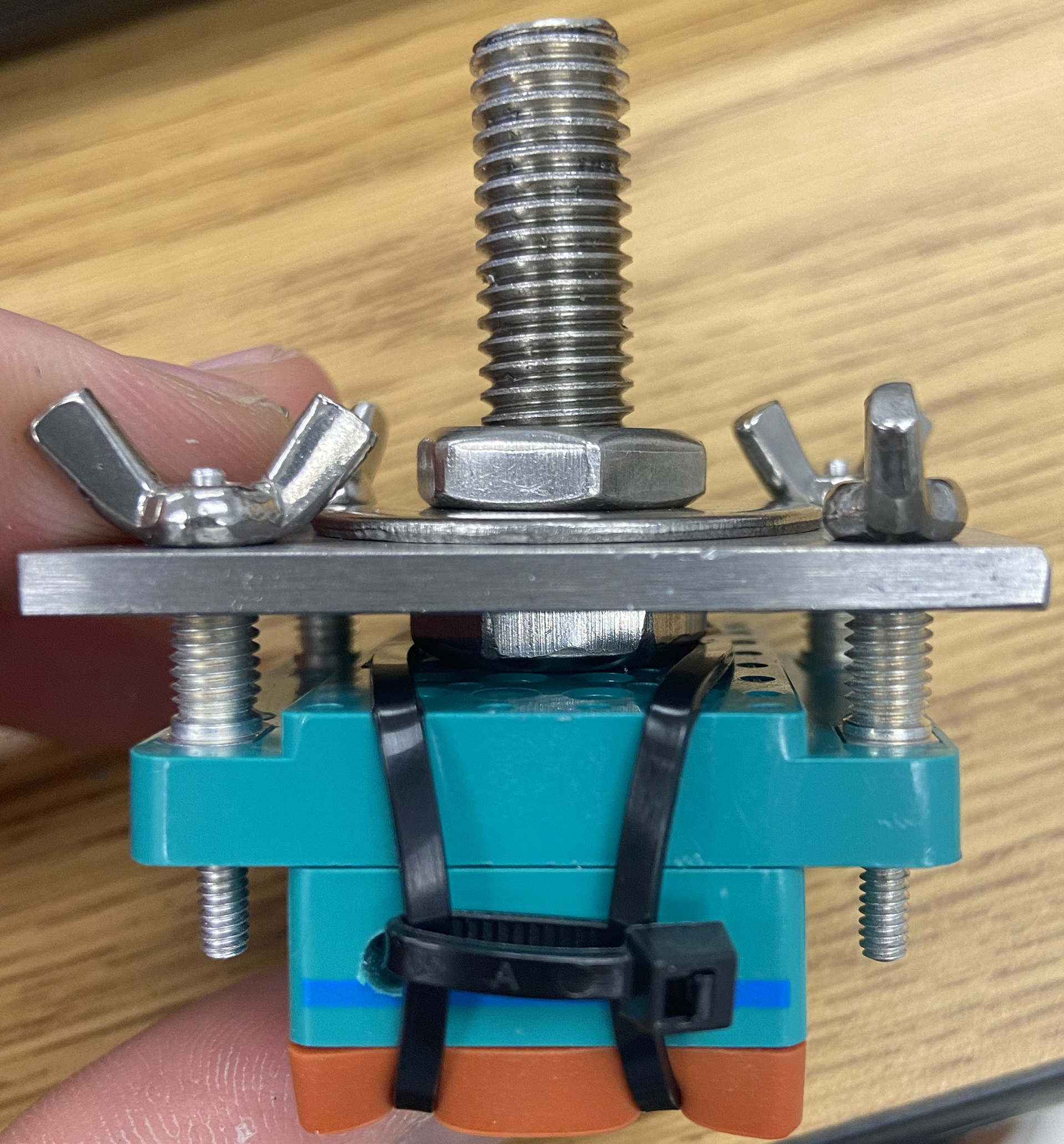

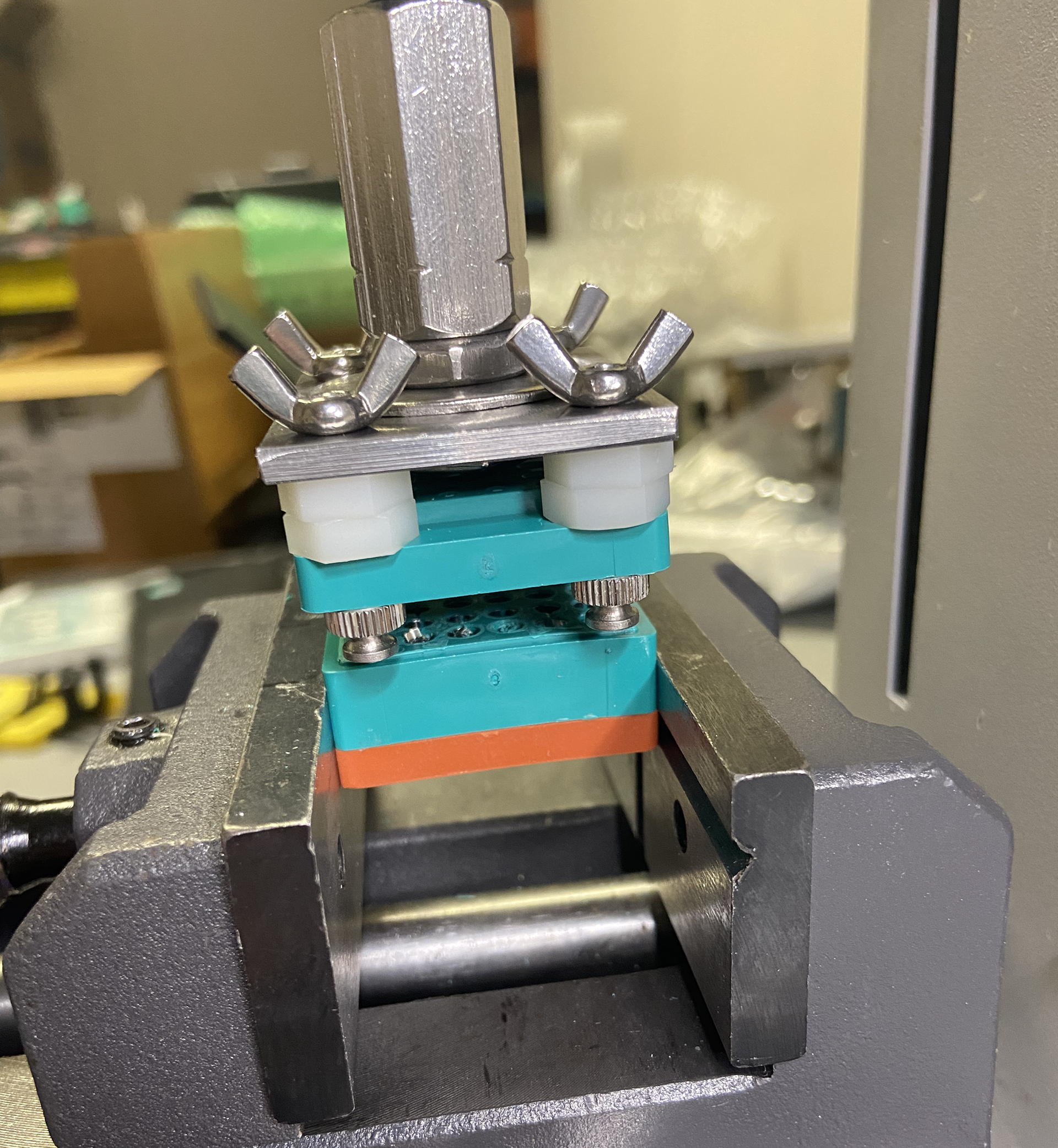

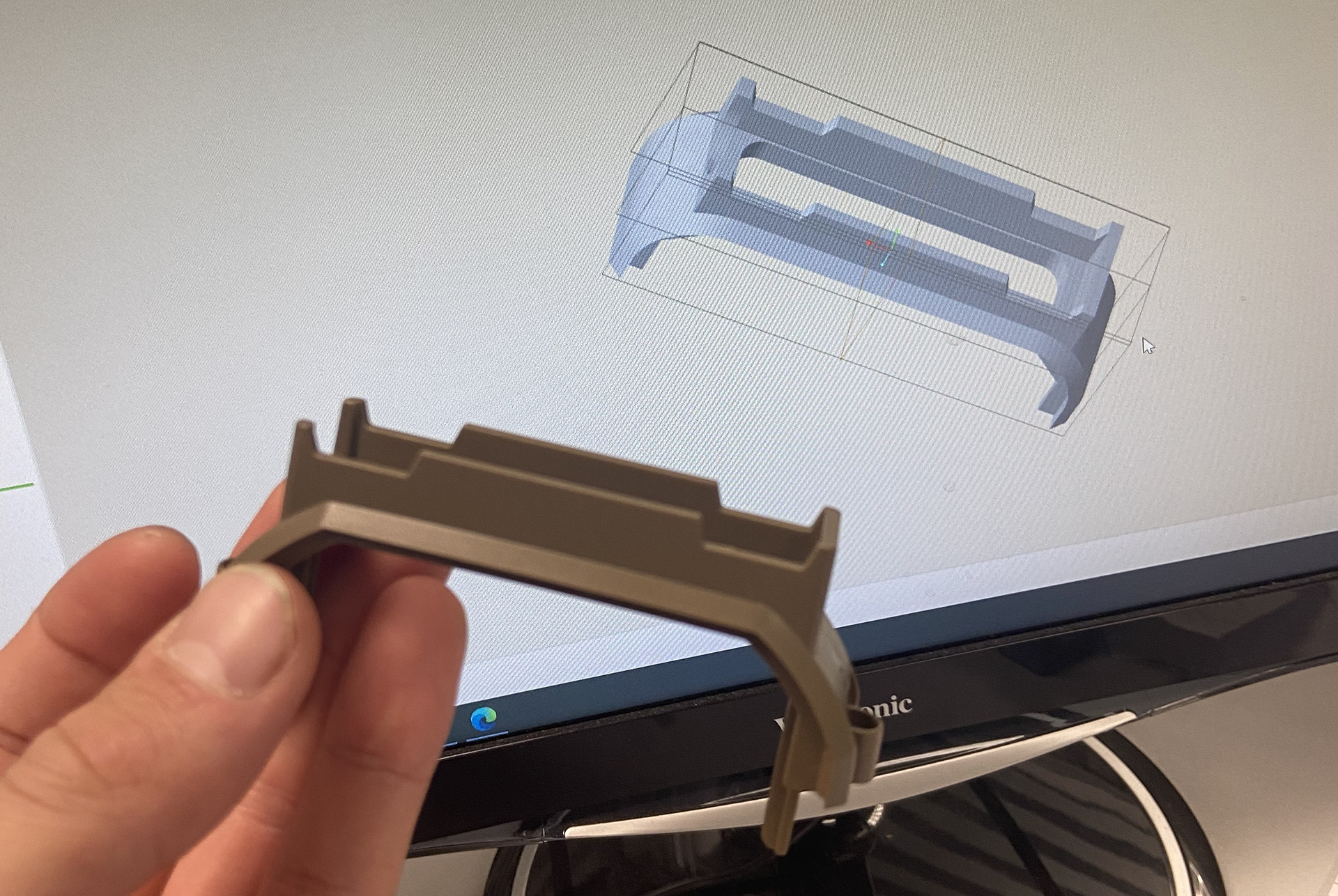

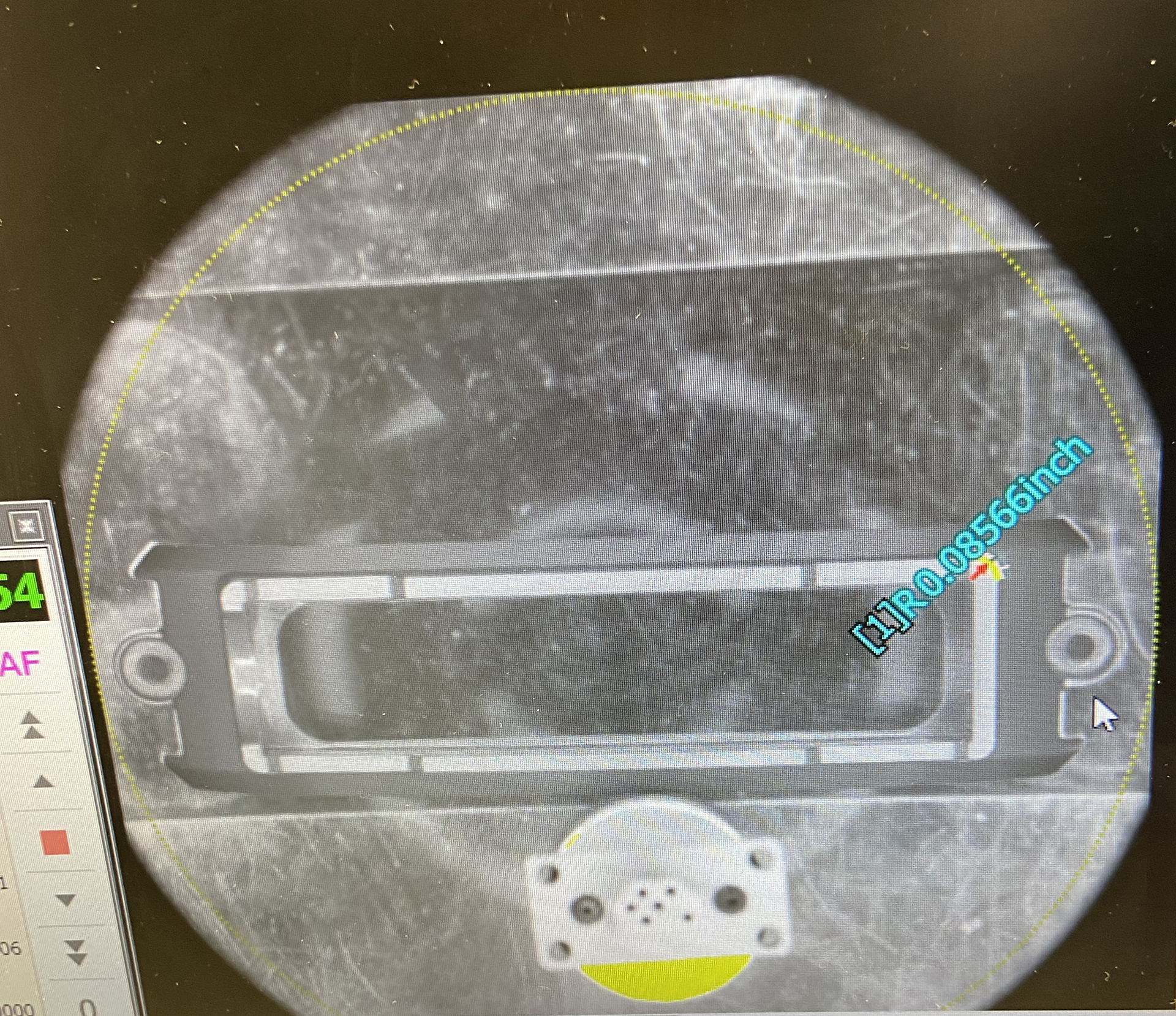

Relay Socket Ultrasonic Welding Investigation

Investigated faulty ultrasonic welds between part components in response to component failures reported by Boeing. Conducted x-ray imaging and cut cross section into connector to identify failure points. Performed extensive pull-apart tests and analyzed stresses concentrations to recommend testing procedure updates. Along with process recommendations, modified existing fixture for stud-less connectors, and prototyped a new fixture for models with built-in studs. Worked with manufacturing engineering team to learn about ultrasonic weld design and optimization.